Save Money And Get Better Results, Too

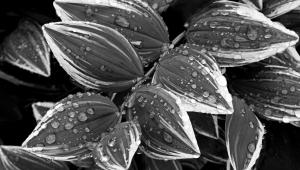

Processing Your First Roll Of Black And White Film

It seems that as technology

strives to make picture taking easier and more digitalized there is

a backlash among many photographers toward rediscovering techniques

and processes of the past. Therefore, I thought this would be an opportune

time to share my technique for processing black and white film. |

|||

The first chemical is the developer.

The developer will convert or reduce the exposed silver halide crystals

in the film's emulsion to black metallic silver. This changes the

invisible or latent image to a visible one. Developers, like film itself,

can be classified by their applications. There are high-speed or high-activity

developers designed to get the most out of a film's inherent speed

but they tend to increase film grain. There are fine grain developers

that use silver solvents, usually sodium sulfite, to reduce the apparent

grain in the film but these can cause a loss of sharpness. High acutance

developers work in conjunction with slow, thin emulsion films to enhance

the sharpness in prints but often at a loss of some film speed. The most

popular class of film developers are what are known as the general purpose

developers. These give good results with a broad range of films and for

many photographers are the only developer they require. |

|||

Next, to render the film no

longer light sensitive and the images permanent, we use fixer. I prefer

a rapid fixer as it reduces the time that the film is wet which helps

to minimize the film grain. To further reduce wet time it is a good idea

to use a hypo clearing bath of some sort after the fixer which will cut

down on the time that the film has to wash. So much for the overview,

let's get to work. |

|||

I suggest a general purpose

developer and highly recommend that you mix your developer with distilled

water rather than tap water. This eliminates another variable and gives

more consistent results. With most developers the recommended processing

temperature is 68°F but check the instructions that came with your

chemicals. Once the tank is full rap the tank on the counter gently to

dislodge any air bubbles adhering to the film and begin inverting the

tank. Note: some tanks cannot be inverted and with these it is very difficult

to get even development of the negatives. Agitation of the developer is

crucial and must be the same every time or your results can vary wildly.

With most films two to three inversions in 5 sec is the proper rate. However,

with T-grain films, such as Kodak T-Max or Ilford Delta, the agitation

should be more vigorous about five inversions every 5 sec. Continue agitating

the film for the first 30 sec that it is in the developer. Remember there

are three things that control the developing process: time, temperature,

and agitation. Keep all three controlled and consistent and your negatives

will come out every time. After the initial 30 sec set the tank down,

give it a quarter turn, and wait 30 sec. After 30 sec has elapsed pick

up the tank, agitate it for 5 sec using the same inversion rhythm as before,

set it down, and again give it a quarter turn. Processing Steps Supplies Hardware Manufacturers/Distributors Brandess/Kalt/Aetna Group (Heico

Perma Wash) Darkroom Innovations Doran Enterprises Dot Line Corp. Eastman Kodak Falcon Safety Products, Inc. JOBO Fototechnic, Inc. Photographer's Formulary,

Inc. |